Operations Practices

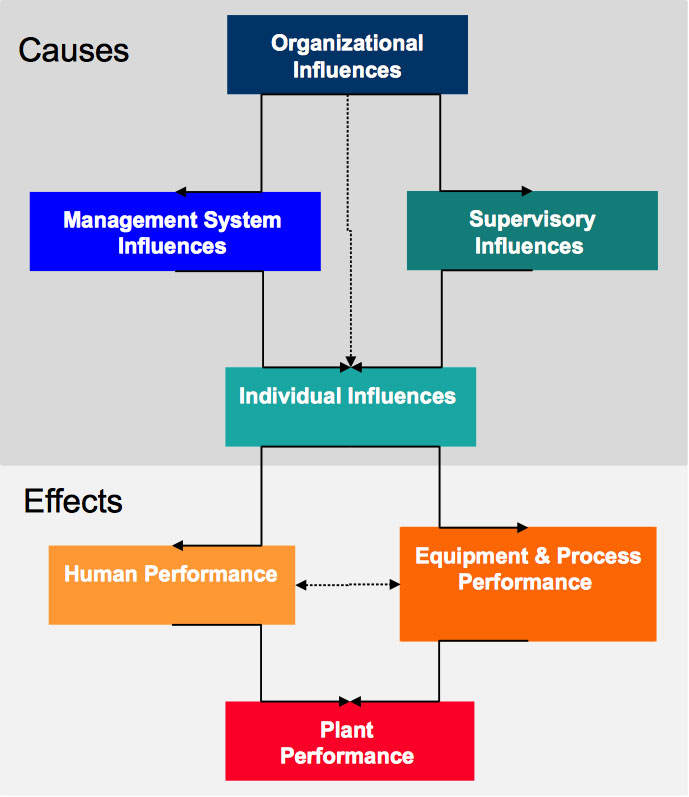

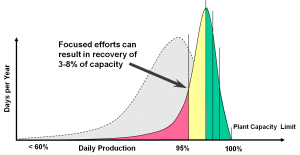

Our operations practices services enable plant management and staff to increase their awareness of how culture, organization structure and policy, workplace design, management systems and use of technology impact performance. Establishing effective operations can reduce the likelihood of abnormal situations and process safety incidents.

Operations Practices Assessment

Operations Practices Assessment

Our effective operations practices assessment service compares your practices against the typical industry practice as well as the industry best practices. Our team can assist you in the implementation of solutions that deliver improved process safety and profitability to your operations.

Our assessment service examines the quality of operations practices in five specific areas:

- Staffing and procedures

- Knowledge and skill development

- Team situation awareness

- Operator alertness and focus

- Continuous improvement

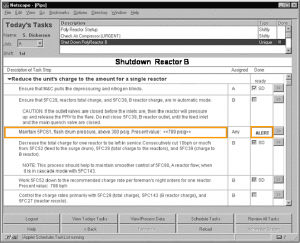

Use of Procedures

Use of Procedures

An effective procedural practice enables plants to achieve effective and efficient routine operations, minimize human-induced disturbances, and enable swift responses to critical or emergency events.

Our procedure design service assesses opportunities to enhance procedural operations and guides the development of procedural content, format, and deployment mechanisms. Our team member, Peter Bullemer, is lead author on the ASM Consortium Guidelines on Effective Procedural Practices. Our procedure design services can help plants achieve compliance with these recommended industry best practices.

Excellence in procedural practices starts with a reasonable policy on what activities need procedural support and requires development of an effective management system to define procedural content, deploy procedures appropriate to the context of use and monitor their effectiveness.

Operator Training

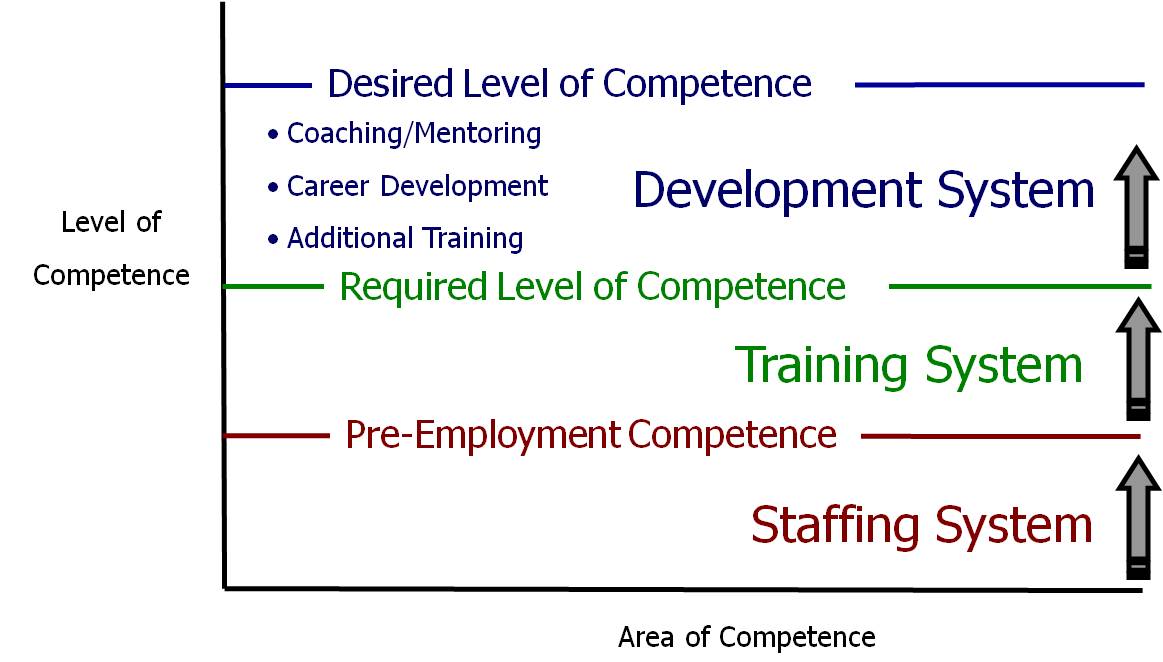

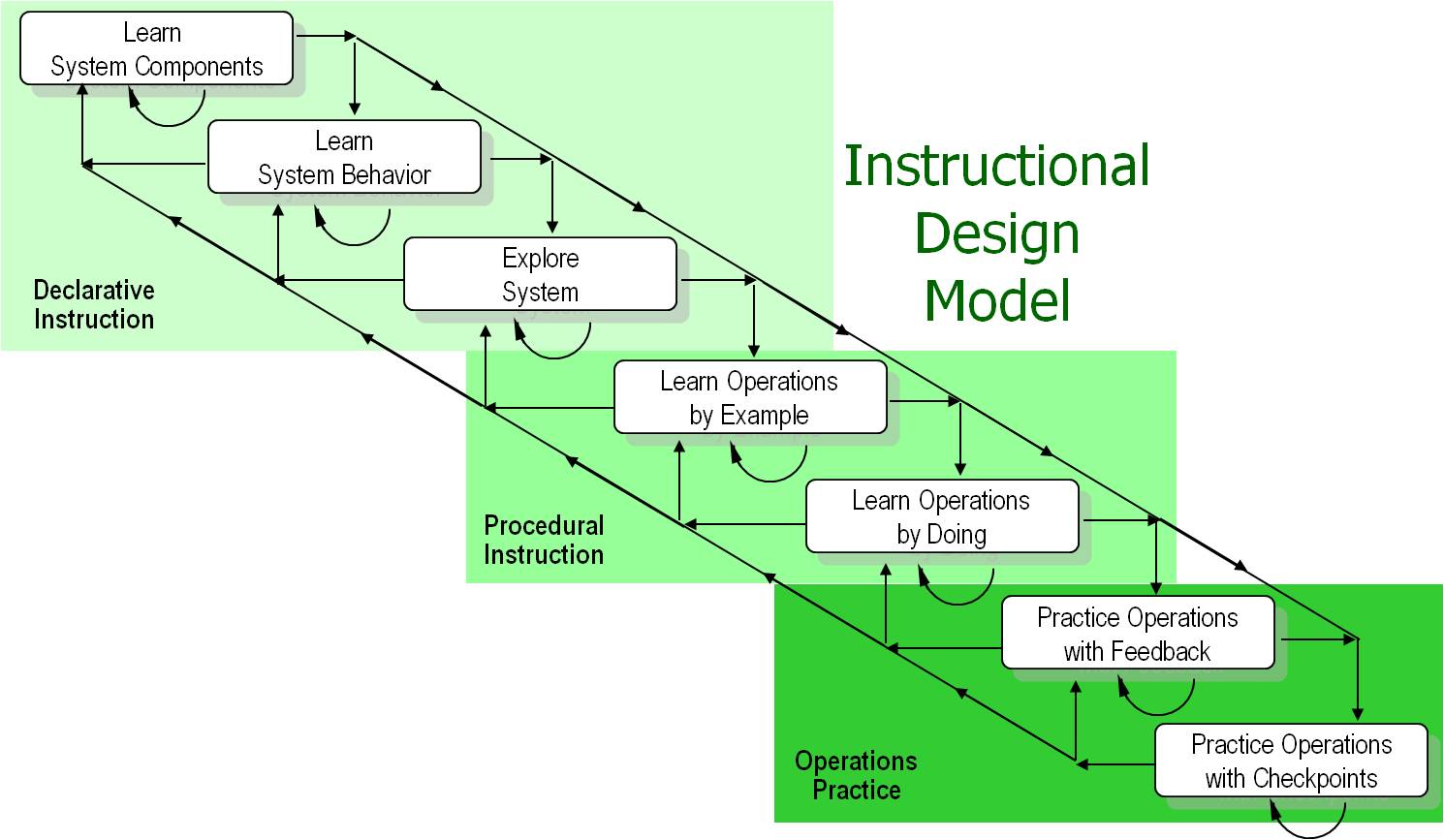

Effective knowledge and skill development is a necessary element of operation practices for the process industries to ensure personnel have the necessary competencies to keep the plant safe, troubleshoot problems and optimize plant performance. The foremost priority is establishing and maintaining the base competencies of operators with respect to their individual job roles and responsibilities, as defined by the competency models for each position. The second priority, an area often overlooked in many training programs, is to develop situation awareness and collaborative competencies that address interactions with other operators and disciplines.

Our operator training service starts the development of a competency-based training philosophy that captures the strategic objectives of the operation training program. Through a series of workshops and structured interviews, our team leads the development of a site-specific training philosophy and set of competency models that map to each operations job position. A job competency model is a valid, observable, and measurable list of the knowledge, skills, and attributes demonstrated through behavior that results in competent performance in a specific job. This competency model establishes a standard of performance for a specific job.

Our operator training service starts the development of a competency-based training philosophy that captures the strategic objectives of the operation training program. Through a series of workshops and structured interviews, our team leads the development of a site-specific training philosophy and set of competency models that map to each operations job position. A job competency model is a valid, observable, and measurable list of the knowledge, skills, and attributes demonstrated through behavior that results in competent performance in a specific job. This competency model establishes a standard of performance for a specific job.

Following the completion of the operator competency, our team works with the site training specialists to define a training program plan. The training program master plan provides the details on the specific method and resources that will be used to ensure operators acquire and maintain the necessary competencies.